Role of Big Data Analytics Capabilities on Green Supply Chain Performance in Pakistan

DOI:

https://doi.org/10.62019/1y0ef318Keywords:

Big Data Analytics Capabilities (BDAC); Green Innovation (GI); Green Supply Chain Integration (GSCI) ; Green Supply Chain Performance (GSCP) and Green Supply Chain (GSC).Abstract

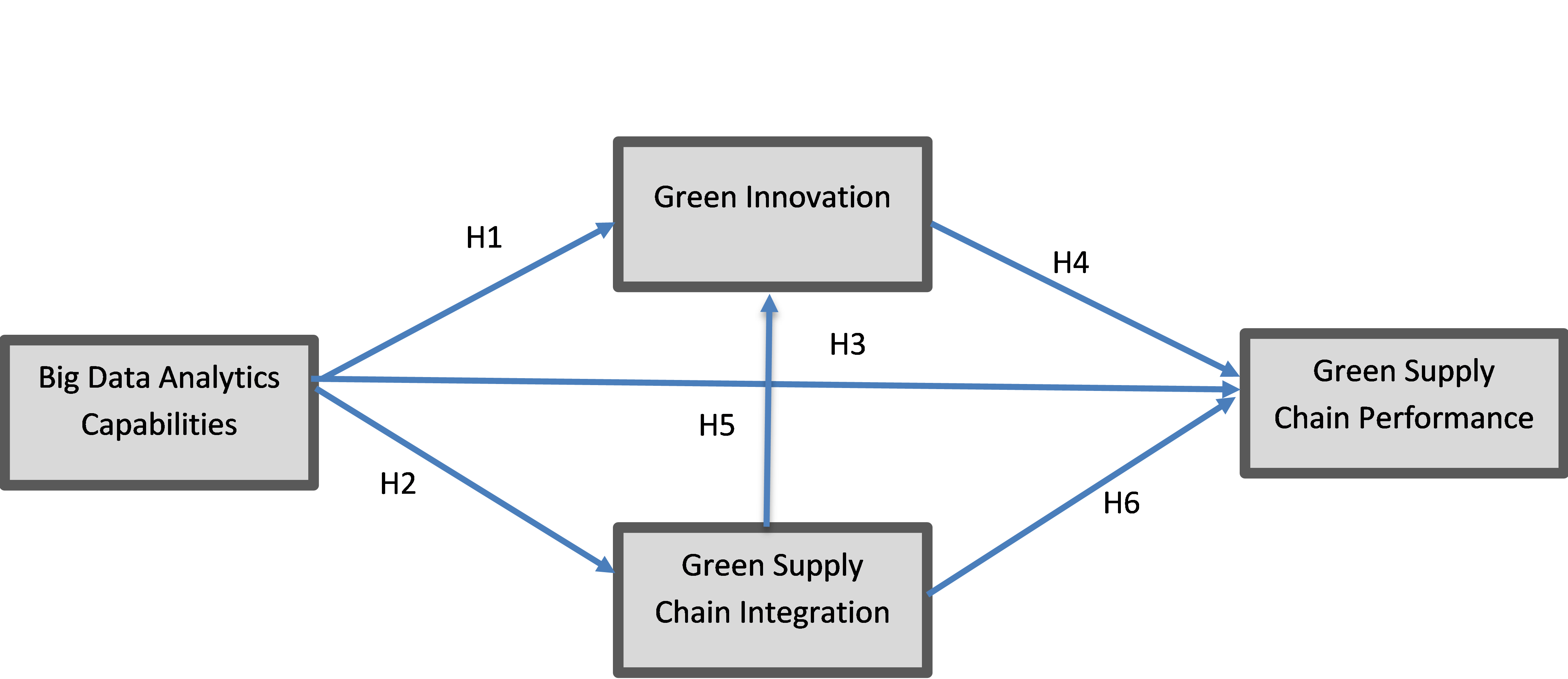

This research delves into the impact of Big Data Analytics Capabilities (BDAC) on the performance of green supply chains in Pakistan. The investigation relies on primary data obtained from the manufacturing sectors, utilizing a sample size of 129 for the final analysis. Structural equation modeling (SEM) through SmartPLS 4 was employed for data analysis. The findings reveal a statistically significant and positive correlation between BDAC and Green Innovation (GI), Green Supply Chain Integration (GSCI), and Green Supply Chain Performance (GSCP). Notably, the study underscores the more pronounced impact of BDAC on Green Innovation compared to its effects on Green Supply Chain Integration and Performance. Several limitations were encountered during the study, including reliance on a questionnaire for primary data collection, the utilization of cross-sectional data, and the focus on a singular context within one country. Despite these constraints, the results offer valuable insights for stakeholders and policymakers in Pakistan's manufacturing sector, supporting effective management of organizational competencies related to big data analytics to enhance both green innovation and green supply chain performance.

References

Afum, E., Osei-Ahenkan, V. Y., Agyabeng-Mensah, Y., Owusu, J. A., Kusi, L. Y., & Ankomah, J. (2020). Green manufacturing practices and sustainable performance among Ghanaian manufacturing SMEs: The explanatory link of green supply chain integration. Management of Environmental Quality, 31(6), 1457–1475. DOI: https://doi.org/10.1108/MEQ-01-2020-0019

Ahmad, K., JianMing, Z., & Rafi, M. (2019). An analysis of academic librarians’ competencies and skills for implementation of big data analytics in libraries: A correlational study. Data Technologies and Applications, 53(2), 201–216. https://doi.org/10.1108/DTA-09-2018-0085 DOI: https://doi.org/10.1108/DTA-09-2018-0085

Ashaari, M. A., Singh, K., Abbasi, G. A., Amran, A., & Liebana-Cabanillas, F. J. (2021). Big data analytics capability for improved performance of higher education institutions in the era of IR 4.0: A multi-analytical SEM and ANN perspective. Technological Forecasting and Social Change, 173, 121119. DOI: https://doi.org/10.1016/j.techfore.2021.121119

Aviles-Gonzalez, J. F., Aviles-Sacoto, S. V., & Cardenas-Barron, L. E. (2017). An overview of tourism supply chains management and optimization models (TSCM–OM). In Handbook of Research on Holistic Optimization Techniques in the Hospitality, Tourism, and Travel Industry (pp. 227–250). IGI Global. DOI: https://doi.org/10.4018/978-1-5225-1054-3.ch010

Awan, U., Bhatti, S. H., Shamim, S., Khan, Z., Akhtar, P., & Balta, M. E. (2022). The role of big data analytics in manufacturing agility and performance: Moderation–mediation analysis of organizational creativity and the involvement of customers as data analysts. British Journal of Management, 33(3), 1200–1220. https://doi.org/10.1111/1467-8551.12549 DOI: https://doi.org/10.1111/1467-8551.12549

Baah, C., Agyeman, D. O., Acquah, I. S. K., Agyabeng-Mensah, Y., Afum, E., Issau, K., & Faibil, D. (2021). Effect of information sharing in supply chains: Understanding the roles of visibility, agility, and collaboration on performance. Benchmarking: An International Journal, 29(2), 434–455. DOI: https://doi.org/10.1108/BIJ-08-2020-0453

Babu, M. M., Rahman, M., & Alam, A. (2021). Exploring big data-driven innovation in the manufacturing sector: Evidence from UK firms. Annals of Operations Research. https://doi.org/10.1007/s10479-021-04077-1 DOI: https://doi.org/10.1007/s10479-021-04077-1

Bag, S., Dhamija, P., Bryde, D. J., & Singh, R. K. (2022). Effect of eco-innovation on green supply chain management, circular economy capability, and performance of SMEs. Journal of Business Research, 141, 60–72. DOI: https://doi.org/10.1016/j.jbusres.2021.12.011

Bag, S., Wood, L. C., Xu, L., Dhamija, P., & Kayikci, Y. (2020). Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resources, Conservation and Recycling, 153, 104559. DOI: https://doi.org/10.1016/j.resconrec.2019.104559

Bahrami, M., & Shokouhyar, S. (2021). The role of big data analytics capabilities in bolstering supply chain resilience and firm performance: A dynamic capability view. Information Technology & People, 35(5), 1621–1651. DOI: https://doi.org/10.1108/ITP-01-2021-0048

Barney, J. (1991). Firm resources and sustained competitive advantage. Journal of Management, 17(1), 99–120. https://doi.org/10.1177/014920639101700108 DOI: https://doi.org/10.1177/014920639101700108

Belhadi, A., Kamble, S. S., Gunasekaran, A., Zkik, K., & Touriki, F. E. (2021). A big data analytics-driven Lean Six Sigma framework for enhanced green performance: A case study. Production Planning & Control, 32(13), 1123–1143.

Benzidia, S., Makaoui, N., & Bentahar, O. (2021). The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technological Forecasting and Social Change, 165, 120557. DOI: https://doi.org/10.1016/j.techfore.2020.120557

Bhatti, S. H., Hussain, W. M. H. W., Khan, J., Sultan, S., & Ferraris, A. (2022). Exploring data-driven innovation: What’s missing between big data analytics capabilities and supply chain innovation? Annals of Operations Research. https://doi.org/10.1007/s10479-022-04772-7 DOI: https://doi.org/10.1007/s10479-022-04772-7

Brinch, M. (2018). Understanding the value of big data in supply chain management: Toward a conceptual framework. International Journal of Operations & Production Management, 38(7), 1589–1614. DOI: https://doi.org/10.1108/IJOPM-05-2017-0268

Burki, U. (2018). Green supply chain management, green innovations, and green practices. In Innovative Solutions for Sustainable Supply Chains (pp. 81–109). Springer. DOI: https://doi.org/10.1007/978-3-319-94322-0_4

Cai, J., Cheng, J., Shi, H., & Feng, T. (2020). The impact of organizational conflict on green supplier integration: The moderating role of governance mechanisms. International Journal of Logistics Research and Applications, 25(2), 143–160. DOI: https://doi.org/10.1080/13675567.2020.1818198

Campbell, D. T., & Fiske, D. W. (1959). Convergent and discriminant validation by the multitrait–multimethod matrix. Psychological Bulletin, 56(2), 81–105. https://doi.org/10.1037/h0046016 DOI: https://doi.org/10.1037/h0046016

Cao, M., & Zhang, Q. (2011). Supply chain collaboration: Impact on collaborative advantage and firm performance. Journal of Operations Management, 29(3), 163–180. DOI: https://doi.org/10.1016/j.jom.2010.12.008

Centobelli, P., Cerchione, R., Cricelli, L., & Strazzullo, S. (2022). Innovation in the supply chain and big data: A critical review. European Journal of Innovation Management, 25(6), 479–497. https://doi.org/10.1108/EJIM-09-2021-0451 DOI: https://doi.org/10.1108/EJIM-09-2021-0451

Chae, B., & Olson, D. L. (2015). Green supply chain management and environmental performance in the U.S. automotive industry. International Journal of Production Economics, 164, 495–507.

Chen, D. Q., Preston, D. S., & Swink, M. (2015). How the use of big data analytics affects value creation in supply chain management. Journal of Management Information Systems, 32(4), 4–39. DOI: https://doi.org/10.1080/07421222.2015.1138364

Ciampi, F., Demi, S., Magrini, A., Marzi, G., & Papa, A. (2021). Big data analytics capabilities and business model innovation: The mediating role of entrepreneurial orientation. Journal of Business Research, 123, 1–13. DOI: https://doi.org/10.1016/j.jbusres.2020.09.023

Creswell, J. W., & Creswell, J. D. (2018). Research design: Qualitative, quantitative, and mixed methods approaches (5th ed.). SAGE.

Davenport, T. H., & Harris, J. (2007). Competing on analytics: The new science of winning. Harvard Business Press.

Dong, Q., Wu, Y., Lin, H., Sun, Z., & Liang, R. (2022). Fostering green innovation for competitive advantages in the big data era. Technology Analysis & Strategic Management, 34(12), 1397–1412.

Dubey, R., Gunasekaran, A., Childe, S. J., Bryde, D. J., Giannakis, M., Foropon, C., & Hazen, B. T. (2020). Big data analytics and AI pathway to operational performance. International Journal of Production Economics, 226, 107599. DOI: https://doi.org/10.1016/j.ijpe.2019.107599

Eckblad, J. W. (1991). How many samples should be taken? BioScience, 41(5), 346–348. https://doi.org/10.2307/1311590 DOI: https://doi.org/10.2307/1311590

Eisenhardt, K. M., & Martin, J. A. (2000). Dynamic capabilities: What are they? Strategic Management Journal, 21(10–11), 1105–1121. DOI: https://doi.org/10.1002/1097-0266(200010/11)21:10/11<1105::AID-SMJ133>3.0.CO;2-E

Etikan, I., Musa, S. A., & Alkassim, R. S. (2016). Comparison of convenience sampling and purposive sampling. American Journal of Theoretical and Applied Statistics, 5(1), 1–4. DOI: https://doi.org/10.11648/j.ajtas.20160501.11

Fazlollahi, A., & Franke, U. (2018). Measuring the impact of enterprise integration on firm performance using DEA. International Journal of Production Economics, 200, 119–129. DOI: https://doi.org/10.1016/j.ijpe.2018.02.011

Fernando, Y., Jabbour, C. J. C., & Wah, W. X. (2019). Environmental innovation and sustainable business performance. Resources, Conservation and Recycling, 141, 8–20. DOI: https://doi.org/10.1016/j.resconrec.2018.09.031

Flynn, B. B., Huo, B., & Zhao, X. (2010). The impact of supply chain integration on performance. Journal of Operations Management, 28(1), 58–71. DOI: https://doi.org/10.1016/j.jom.2009.06.001

Galbraith, J. R. (1974). Organization design: An information processing view. Interfaces, 4(3), 28–36. DOI: https://doi.org/10.1287/inte.4.3.28

Gang, W., Gunasekaran, A., Ngai, E., & Papadopoulos, T. (2016). Big data analytics in logistics and SCM. International Journal of Production Economics, 176, 98–110.

Gliem, J. A., & Gliem, R. R. (2003). Calculating, interpreting, and reporting Cronbach’s alpha reliability coefficient for Likert-type scales. Midwest Research to Practice Conference, 82–88.

Govindan, K., Fattahi, M., & Keyvanshokooh, E. (2015). Supply chain network design under uncertainty. European Journal of Operational Research, 247(1), 157–189.

Gunasekaran, A., Papadopoulos, T., Dubey, R., Wamba, S. F., Childe, S. J., Hazen, B., & Akter, S. (2017). Big data & predictive analytics for supply chain and organizational performance. Journal of Business Research, 70, 308–317. DOI: https://doi.org/10.1016/j.jbusres.2016.08.004

Hair, J. F., Jr., Sarstedt, M., Matthews, L. M., & Ringle, C. M. (2016). Identifying and treating unobserved heterogeneity with FIMIX-PLS: Part I—Method. European Business Review, 28(1), 63–76. DOI: https://doi.org/10.1108/EBR-09-2015-0094

Hamid, A., Sami, W., & Sidek, M. (2017). Discriminant validity assessment: Fornell–Larcker vs. HTMT. Journal of Physics: Conference Series, 890, 012163. DOI: https://doi.org/10.1088/1742-6596/890/1/012163

Hart, S. L. (1995). A natural-resource-based view of the firm. Academy of Management Review, 20(4), 986–1014. DOI: https://doi.org/10.2307/258963

Hazen, B. T., Boone, C. A., Ezell, J. D., & Jones-Farmer, L. A. (2014). Data quality for data science in SCM. International Journal of Production Economics, 154, 72–80. DOI: https://doi.org/10.1016/j.ijpe.2014.04.018

Helfat, C. E., & Peteraf, M. A. (2009). Understanding dynamic capabilities. Strategic Organization, 7(1), 91–102. DOI: https://doi.org/10.1177/1476127008100133

Henseler, J., Hubona, G., & Ray, P. A. (2016). Using PLS path modeling in new technology research. Industrial Management & Data Systems, 116(1), 2–20. DOI: https://doi.org/10.1108/IMDS-09-2015-0382

Henseler, J., Ringle, C. M., & Sinkovics, R. R. (2009). The use of PLS path modeling in international marketing. In R. R. Sinkovics & P. N. Ghauri (Eds.), New Challenges to International Marketing (Vol. 20, pp. 277–319). Emerald. DOI: https://doi.org/10.1108/S1474-7979(2009)0000020014

Ifinedo, P. (2011). Internet/e-business technologies acceptance in Canada’s SMEs. Internet Research, 21(3), 255–281. DOI: https://doi.org/10.1108/10662241111139309

Imran, R., Alraja, M. N., & Khashab, B. (2021). Sustainable performance and green innovation: GHRM and big data as antecedents. IEEE Transactions on Engineering Management. https://doi.org/10.1109/TEM.2021.3114256 DOI: https://doi.org/10.1109/TEM.2021.3114256

Iqbal, M., Kazmi, S. H. A., Manzoor, A., Soomrani, A. R., Butt, S. H., & Shaikh, K. A. (2018). A study of big data for business growth in SMEs. 2018 International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), 1–7. https://doi.org/10.1109/ICOMET.2018.8346368 DOI: https://doi.org/10.1109/ICOMET.2018.8346368

Jajja, M. S. S., Chatha, K. A., & Farooq, S. (2018). Impact of supply chain risk on agility performance: Mediating role of SCI. International Journal of Production Economics, 205, 118–138. DOI: https://doi.org/10.1016/j.ijpe.2018.08.032

Jayaraman, R., & Luo, Y. (2019). Achieving end-to-end visibility in green supply chains using big data. In Proceedings/Chapter [details needed].

Junaid, M., Zhang, Q., & Syed, M. W. (2022). Effects of sustainable supply chain integration on green innovation and firm performance. Sustainable Production and Consumption, 30, 145–157. DOI: https://doi.org/10.1016/j.spc.2021.11.031

Kong, T., Feng, T., & Huo, B. (2021). Green supply chain integration and financial performance. Business Strategy and the Environment, 30(5), 2255–2270. DOI: https://doi.org/10.1002/bse.2745

Kong, T., Feng, T., Huang, Y., & Cai, J. (2020). Converting GSCI efforts into green innovation. Sustainable Development, 28(5), 1106–1121. DOI: https://doi.org/10.1002/sd.2062

Lamba, K., Singh, S. P., & Mishra, N. (2019). Integrated decisions for supplier selection and lot-sizing under carbon regulations in a big data environment. Computers & Industrial Engineering, 128, 1052–1062. DOI: https://doi.org/10.1016/j.cie.2018.04.028

Lee, C. K. H. (2017). A GA-based optimisation model for anticipatory shipping in Retail 4.0. International Journal of Production Research, 55(2), 593–605. DOI: https://doi.org/10.1080/00207543.2016.1221162

Lee, I., & Mangalaraj, G. (2022). Big data analytics in supply chain management: A systematic literature review. Big Data and Cognitive Computing, 6(1), 17. DOI: https://doi.org/10.3390/bdcc6010017

Lisi, W., Zhu, R., & Yuan, C. (2020). Embracing green innovation via GSC learning. Sustainable Development, 28(1), 155–168. DOI: https://doi.org/10.1002/sd.1979

Lo, S. M., Zhang, S., Wang, Z., & Zhao, X. (2018). Relationship quality, supplier development, and GSCI. Journal of Cleaner Production, 202, 524–535. DOI: https://doi.org/10.1016/j.jclepro.2018.08.175

Mani, V., Delgado, C., Hazen, B. T., & Patel, P. (2017). Mitigating supply chain risk via sustainability using big data analytics. Sustainability, 9(4), 608. DOI: https://doi.org/10.3390/su9040608

Mavi, R. K., & Mavi, N. K. (2021). National eco-innovation analysis with big data. Technological Forecasting and Social Change, 162, 120369. DOI: https://doi.org/10.1016/j.techfore.2020.120369

Michalos, A. C. (2014). Encyclopedia of quality of life and well-being research. Springer. DOI: https://doi.org/10.1007/978-94-007-0753-5

Nguyen, T., Zhou, L., Spiegler, V., Ieromonachou, P., & Lin, Y. (2018). Big data analytics in SCM: A review. Computers & Operations Research, 98, 254–264. DOI: https://doi.org/10.1016/j.cor.2017.07.004

Papadopoulos, T., Gunasekaran, A., Dubey, R., Altay, N., Childe, S. J., & Fosso-Wamba, S. (2017). The role of big data in explaining disaster resilience in supply chains. Journal of Cleaner Production, 142, 1108–1118. DOI: https://doi.org/10.1016/j.jclepro.2016.03.059

Pawar, P. V., & Paluri, R. A. (2022). Big data analytics in logistics and SCM: A review. [Journal details needed]. DOI: https://doi.org/10.1177/09722629221091655

Peng, H., Shen, N., Liao, H., & Wang, Q. (2020). Green knowledge integration and GSC performance. Journal of Cleaner Production, 259, 120821. DOI: https://doi.org/10.1016/j.jclepro.2020.120821

Peng, Y., Zhao, X., Sun, H., & Yang, Y. (2019). Leveraging big data to drive competitive advantage. Journal of Organizational Computing and Electronic Commerce, 29(3), 229–245.

Podsakoff, P. M., MacKenzie, S. B., Lee, J.-Y., & Podsakoff, N. P. (2003). Common method biases in behavioral research. Journal of Applied Psychology, 88(5), 879–903. DOI: https://doi.org/10.1037/0021-9010.88.5.879

Preston, F., & Miller, L. (2019). Circular economy business models: The state of play in the UK. University of Exeter.

Qi, Y., Huo, B., Wang, Z., & Yeung, H. Y. J. (2017). Operations and supply chain strategies: Integration and performance. International Journal of Production Economics, 185, 162–174. DOI: https://doi.org/10.1016/j.ijpe.2016.12.028

Razaghi, S., & Shokouhyar, S. (2021). Impacts of BDA management capabilities and supply chain integration on global sourcing. The Bottom Line, 34(2), 198–223. DOI: https://doi.org/10.1108/BL-11-2020-0071

Rodríguez-González, R. M., Maldonado-Guzmán, G., & Madrid-Guijarro, A. (2022). Green strategies, eco-innovation, and performance. Corporate Social Responsibility and Environmental Management, 29(4), 779–794. DOI: https://doi.org/10.1002/csr.2233

Sarkis, J., Zhu, Q., & Lai, K. H. (2017). An organizational theoretic review of GSCM literature. International Journal of Production Economics, 149, 159–174.

Saunders, M., Lewis, P., & Thornhill, A. (2019). Research methods for business students (8th ed.). Pearson.

Seman, N. A. A., Zakuan, N., Jusoh, A., Arif, M. S. M., & Saman, M. Z. M. (2012). GSCM and green innovation. Procedia – Social and Behavioral Sciences, 57, 453–457. DOI: https://doi.org/10.1016/j.sbspro.2012.09.1211

Seyedan, M., & Mafakheri, F. (2020). Predictive big data analytics for demand forecasting. Journal of Big Data, 7(1), 1–22. DOI: https://doi.org/10.1186/s40537-020-00329-2

Shafique, M. N., Rashid, A., Bajwa, I. S., Kazmi, R., Khurshid, M. M., & Tahir, W. A. (2018). Effect of IoT capabilities and energy consumption behaviour on GSCI. Applied Sciences, 8(12), 2481. DOI: https://doi.org/10.3390/app8122481

Shan, S., Luo, Y., Zhou, Y., & Wei, Y. (2019). Big data analysis adaptation and competitive advantages. Technology Analysis & Strategic Management, 31(4), 406–420. DOI: https://doi.org/10.1080/09537325.2018.1516866

Sharma, R., Shishodia, A., Gunasekaran, A., Min, H., & Munim, Z. H. (2022). The role of AI in supply chain management. International Journal of Production Research, 60(11), 1–24. DOI: https://doi.org/10.1080/00207543.2022.2029611

Song, M., Fisher, R., & Kwoh, Y. (2019). Technological challenges of green innovation with large-scale data. Technological Forecasting and Social Change, 144, 361–368. DOI: https://doi.org/10.1016/j.techfore.2018.07.055

Sun, Y., & Sun, H. (2021). Green innovation strategy and ambidextrous green innovation: The mediating effects of GSCI. Sustainability, 13(9), 4876. DOI: https://doi.org/10.3390/su13094876

Tabachnick, B. G., & Fidell, L. S. (2007). Using multivariate statistics (5th ed.). Allyn & Bacon.

Tavakol, M., & Dennick, R. (2011). Making sense of Cronbach’s alpha. International Journal of Medical Education, 2, 53–55. DOI: https://doi.org/10.5116/ijme.4dfb.8dfd

Teece, D. J. (2007). Explicating dynamic capabilities. Strategic Management Journal, 28(13), 1319–1350. DOI: https://doi.org/10.1002/smj.640

Teece, D. J., Pisano, G., & Shuen, A. (1997). Dynamic capabilities and strategic management. Strategic Management Journal, 18(7), 509–533. DOI: https://doi.org/10.1002/(SICI)1097-0266(199708)18:7<509::AID-SMJ882>3.0.CO;2-Z

Wamba, S. F., Gunasekaran, A., Akter, S., Ren, S. J.-F., Dubey, R., & Childe, S. J. (2017). Big data analytics and firm performance: Effects of dynamic capabilities. Journal of Business Research, 70, 356–365. DOI: https://doi.org/10.1016/j.jbusres.2016.08.009

Wang, G., Feng, T., Zhao, X., & Song, Y. (2018). Supplier trust, relationship commitment, and green supplier integration. Sustainable Development, 26(6), 879–889. DOI: https://doi.org/10.1002/sd.1857

Wang, G., Gunasekaran, A., Ngai, E. W., & Papadopoulos, T. (2016). Big data analytics in logistics and SCM. International Journal of Production Economics, 176, 98–110. DOI: https://doi.org/10.1016/j.ijpe.2016.03.014

Wang, J., & Feng, T. (2022). Supply chain ethical leadership and GSCI: A moderated mediation analysis. International Journal of Logistics Research and Applications. https://doi.org/10.1080/13675567.2021.2022640 DOI: https://doi.org/10.1080/13675567.2021.2022640

Waqas, M., Honggang, X., Ahmad, N., Khan, S. A. R., & Iqbal, M. (2021). BDA as a roadmap toward green innovation and environmental performance. Journal of Cleaner Production, 323, 128998. DOI: https://doi.org/10.1016/j.jclepro.2021.128998

Waqas, M., & Tan, L. (2023). Big data analytics capabilities for reinforcing green production and sustainable firm performance. Environmental Science and Pollution Research, 30, 14318–14336. DOI: https://doi.org/10.1007/s11356-022-23082-w

Wong, C. Y., Wong, C. W., & Boon-itt, S. (2020). Effects of GSCI and green innovation on environmental and cost performance. International Journal of Production Research, 58(15), 4589–4609. DOI: https://doi.org/10.1080/00207543.2020.1756510

Wu, G. (2013). The influence of GSCI and environmental uncertainty on green innovation. Supply Chain Management: An International Journal, 18(5), 539–552. https://doi.org/10.1108/SCM-06-2012-0201 DOI: https://doi.org/10.1108/SCM-06-2012-0201

Xi, M., Fang, W., & Feng, T. (2022). Green intellectual capital and GSCI: The mediating role of supply chain transformational leadership. Journal of Intellectual Capital. https://doi.org/10.1108/JIC-12-2021-0333 DOI: https://doi.org/10.1108/JIC-12-2021-0333

Yang, Q., Geng, R., Feng, T., & Welford, R. (2020). Macro- and micro-institutional environments and GSCI effectiveness. Business Strategy and the Environment, 29(4), 1695–1713. DOI: https://doi.org/10.1002/bse.2462

Yang, Z., & Lin, Y. (2020). Effects of supply chain collaboration on green innovation performance. Sustainable Production and Consumption, 23, 1–10. DOI: https://doi.org/10.1016/j.spc.2020.03.010

Yildizbasi, A., & Arioz, Y. (2022). Green supplier selection integrating big data analytics and fuzzy MCDM. Soft Computing, 26(1), 253–270. DOI: https://doi.org/10.1007/s00500-021-06477-8

Yu, W., Zhao, G., Liu, Q., & Song, Y. (2021). Role of BDAC in integrated hospital supply chains. Technological Forecasting and Social Change, 163, 120417. DOI: https://doi.org/10.1016/j.techfore.2020.120417

Zhang, X., Chen, R., & Liu, C. (2018). Resource efficiency and waste reduction via big data analytics. [Journal details needed].

Zhou, K. Z., Zhang, Q., & Zhao, S. (2019). The big data technology landscape: A contemporary review. The Journal of Strategic Information Systems, 28(2), 165–174.

Zhu, Q., & Sarkis, J. (2016). Green supply chain management and organizational performance. Industrial Marketing Management, 53, 140–152.

Zollo, M., & Winter, S. G. (2002). Deliberate learning and the evolution of dynamic capabilities. Organization Science, 13(3), 339–351. DOI: https://doi.org/10.1287/orsc.13.3.339.2780

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Minhaj Ikram, Ali Ismail

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.